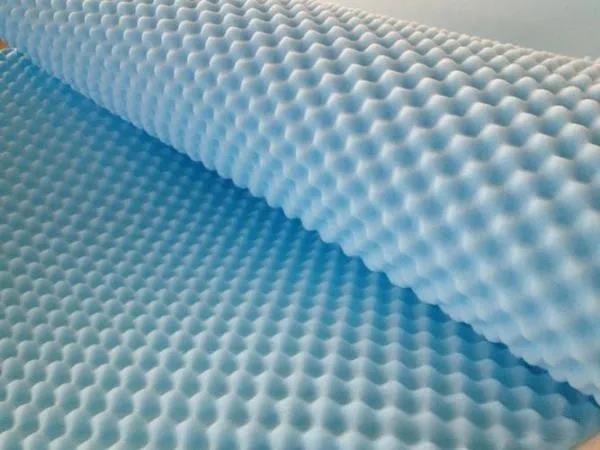

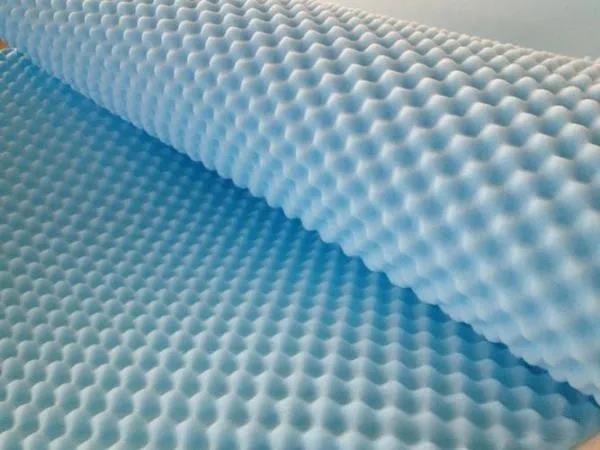

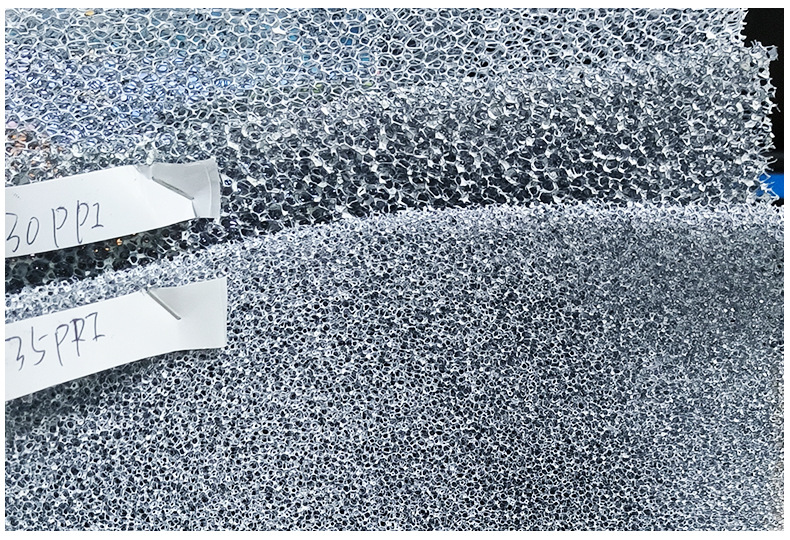

The breathability of the wavy sponge greatly improves comfort

The breathability of the wavy sponge greatly improves comfort

Oct .21.2024

The breathability of the wave sponge significantly increases the comfort of the product by providing air circulation, reducing heat and moisture buildup, improving hygiene and durability, and enhancing functionality and aesthetics.

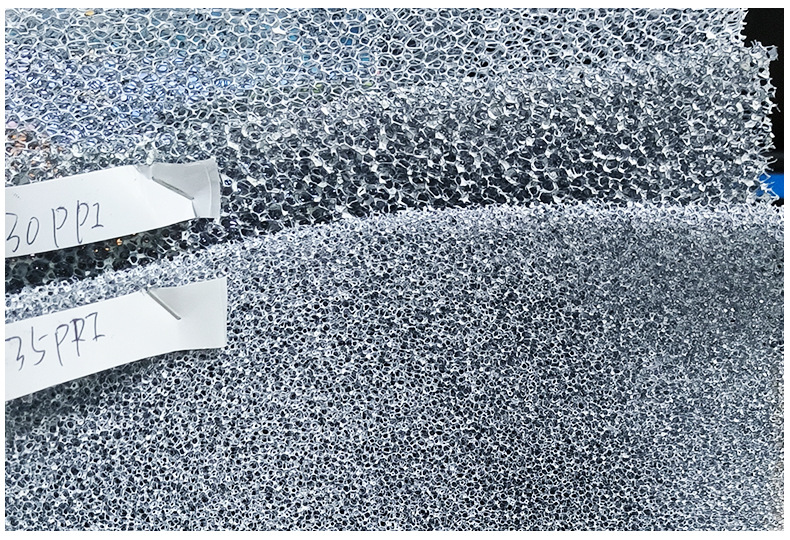

What is Photocatalyst filter and its Application

What is Photocatalyst filter and its Application

Oct .16.2024

Photocatalytic filters use the reaction of ultraviolet light and titanium dioxide to break down organic pollutants and harmful gases in the air, such as bacteria, viruses and VOCs. Photocatalysis is a relatively new air purification technology suitable fo

Surgical Sponge Dressing

Surgical Sponge Dressing

Oct .14.2024

The main material of surgical sponge dressing is medical PVA sponge. PVA medical grade macroporous sponge has excellent liquid absorption function, high comfort level, high strength, and soft appearance when touched with human body, which is widely used i

The breathability of the wavy sponge greatly improves comfort

The breathability of the wavy sponge greatly improves comfort

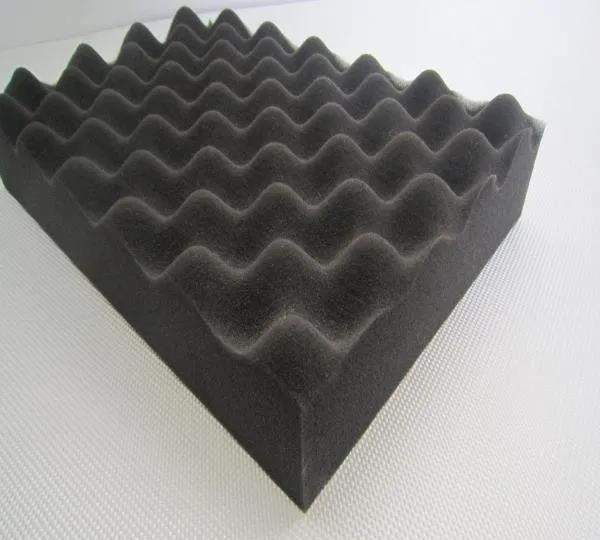

How does a wavy sponge improve blood circulation

How does a wavy sponge improve blood circulation

What is Photocatalyst filter and its Application

What is Photocatalyst filter and its Application

Surgical Sponge Dressing

Surgical Sponge Dressing